Manufacturing Engineering

Manufacturing Engineering Scope :

Manufacturing Science & Engineering has emerged as an independent discipline catering to the global need. Thus, the department was started in the year 1996 with an annual intake of 30 with the following objectives and core values.

- Promote academic excellence.

- Raise the level of knowledge, competence and skills in the area of manufacturing engineering.

- Implementation of new curriculum and innovative instructional methods, such as self-paced learning, problem-solving projects, training in industry.

- Establish and expand research capabilities for students and faculty.

- Consulting projects that will serve industry and the community.

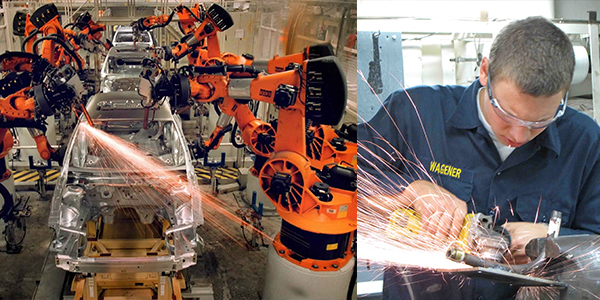

- Exposure and experience with advanced manufacturing technologies such as Robotics, F.M.S, C.I.M, Non-conventional machining etc.

The department offers a four year undergraduate degree course in Manufacturing Science and Engineering leading to B.Tech. degree. Core manufacturing subjects, topics on advanced production technologies. IT related subjects and topics on managerial skills are carefully designed and put in the course structure to produce industry ready professionals. The job opportunities lie both in core manufacturing sectors and IT sectors. Due to high rate of globalization and industrialization, the scope of employment for manufacturing professionals is vast and is ever increasing.

Manufacturing Engineering Subjects / Syllabus :

- Mathematics I.

- Chemistry.

- English for Communication

- Basic Electronics.

- Mechanics.

- Engineering Drawing and Graphics.

- EAA I.

- Electrical Technology.

- Introduction to Manufacturing Processes.

- Mathematics II.

- Physics.

- Programming and Data Structure.

- Basic Electronics.

- Engineering Drawing and Graphics.

- EAA II.

- Electrical Technology.

- Introduction to Manufacturing Processes.

- Mathematics III (Module 3).

- Operations Research I.

- Computer Graphics and Solids Modeling

- Breadth I (H.S.S I).

- Workshop Processes.

- EAA III.

- Mathematics III (Module 2).

- Breadth II.

- Breadth III.

- Mechanisms and Machines.

- Casting Forming and Welding.

- Thermodynamics.

- EAA IV.

- IT for Product Realization.

- Non-traditional Manufacturing Processes.

- Robots and Computer Controlled Machines.

- Machine Tools and Machining.

- Elective I.

- Breadth IV (IT).

- Project.

- Breadth V (Management).

- Finite Element Methods in Engineering.

- Emerging Trends in Manufacturing Technology.

- Principles of Machine Design.

- Enterprise Integration.

- Elective (HSS II).

- Quality Assurance and Reliability.

- Process Dynamics and Adaptive Control.

- Evolutionary Computing.

- Elective II.

- Elective III.

- Project.

- Industrial Training.

- Computer Integrated Manufacturing.

- Breadth VI.

- Elective IV.

- Elective V.

- Elective VI.

- Comprehensive Viva Voce.

- Project.

Manufacturing Engineering Eligibility & Admission Process:

- Candidates who have passed 10+2 or equivalent , with a minimum 60% marks.

- The candidate must have a valid Joint Entrance Examination score.

Colleges :

- Ghousia College of Engineering.

- Indian Institute of Technology Kharagpur.

- M.S. Ramaiah College of Engineering.

- P.E.S. Institute of Technology.

- Siddaganga Institute of Technology.

- University Visveswariah College of Engineering.

Jobs Prospects & Salaries :

Manufacturing engineers often work in teams. They will frequently meet with other engineers and others outside engineering to review the manufacturing process, goals, and current status. Manufacturing engineers may be involved in workforce planning and use, workflow, and the design and space planning for the manufacturing process. They may be involved in product planning, providing input into original product design — with an eye to what will be required to ultimately manufacture the product.

Their expertise in production efficiency is helpful in product design, and packaging planning. Manufacturing engineers may work with suppliers and other vendors to develop and review part specification, pricing, and delivery planning. They will be involved in quality control, and meeting standards for the final product. They may also focus on planning production times, cost estimates, and marketing decisions.